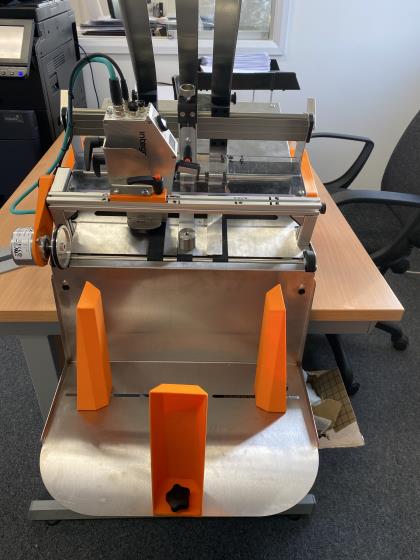

N&N 600 Litre Vacuum Tumbler

N&N 600 Litre Vacuum Tumbler

N&N 600 litre Vacuum Tumbler

Tilting Tumbler

Built in Vacuum Pump

Plug & Play Machine

Can be set up to run various program mixers and vacuum tumbling

Cement mixer type tumbler with PLC Mitsubishi touch screen control panel and built in vacuum pump.

Ideal for mixing and tumbling various products with or without vacuum

The Tumbler has a variable direction of rotation and a variable position angle.

The mixing process is carried out at atmospheric pressure or under vacuum

Suitable for use within a variety of applications: meat, poultry, seafood, vegetables or cereals industry.

Fully programmable: speed, time and vacuum.

Tumbler discharges the product straight into 200 litre tote bins.

Height 1700mm

Length 1930mm

Width 1460mm

Machine will lift to 2100mm

Discharge into Tote Bins

Cement type Tumbler with built in vacuum pump plug and play machine

Discharges product straight into Tote bins can be supplied with Tote Bin loader

We can supply all machines from the N&N range of Tilting Vacuum Tumblers .

The N&N 600 litre Vacuum Tumbler is an ideal machine for mixing, marinating all types of food products within the meat, poultry, fish, vegetables, dairy, cereal, confectionery, petfood and sandwich filling industry.

Also N&N Vacuum Tumblers produce a gentle mixing action which reduces particulate destruction maintaining the product structure and its original quality, the tilting and turning of the Vacuum Tumbler is very gentle .

For further information on the N&N 600L Vacuum Tumbler or any of our other machines, please do not hesitate to contact our sales team at Total Food Machines.

Call +44 (0)28 90 994 202 or email sales@totalfoodmachines.com