Total Food Machines work in partnership with Rotech leading supplier of Sleeve and Pouch Printing Machines also Coding and Marking Solutions.

Rotech deign and manufacture high quality coding and marking equipment to customers in all sectors across the UK and globally.

Rotech have an extensive knowledge of the packaging industry and the printing technologies that are used across multiple sectors.

Sleeves are becoming an increasingly popular packaging choice for food products; particularly ready meals packaged in trays, tubs or pots.

However, date or batch coding onto sleeves online can present the following problems

- Certain print areas may be hard to access

- Tall tubs or pots can be unstable and difficult to guide down a packaging line

- When placed around trays, sleeves can move making accurate code placement difficult

By taking the process offline, these issues can be solved. We have several systems ideally suited to the printing and coding of sleeves.

RF LITE

The RF Lite food sleeve coding system offers the ideal solution for companies looking to automate their date coding for the first time. Fitted with clean thermal inkjet technology, the RF Lite is ideal for clear, concise date or batch coding onto sleeves. It also suits larger operations who are looking to install dedicated marking systems on multiple production lines.

RF AUTO

The RF Auto food sleeve, carton and bag coding machine is an operator friendly, heavy duty and high speed machine. Due to the auto gating technology, the RF Auto can automatically adjust to accommodate varying thicknesses of product leading to reduced set up time and waste.

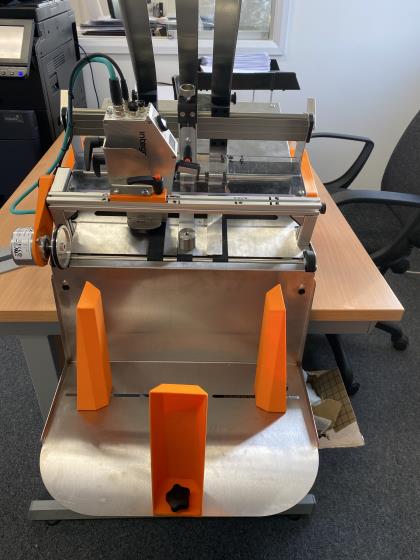

RF LITE TT

The RF Lite TT is a innovative pouch and lid printing machine. The RF Lite TT is a very cost effective system for companies looking to print directly onto lids, cards and pouches. It is also perfect for the replacement of labels. IT delivers large ares of print which can include graphics, logos and barcodes and there is even the possibility to print text.

RF1 FEEDER

The RF1 Feeder is the most versatile model in the rotech range being able to handle a wide range of packaging in it's flat form, most notably thin items such as blister cards, medical pouches and lidding material. This all makes it ideal for standalone coding, marking or labelling system when fitted with a printer and/or labeller. Continuous operation of the feeder gives very high throughput rates at deceptively low machine speeds.

RF COMPLIANCE

The RF Compliance takes the complexity out of sterilisation. It has the ability to generate, print and verify serialised 2d codes on to a range of packaging formats. The RF Compliance offers a reliable, instant and easy to use solution for pharmaceutical and medical manufacturers. The system comes with a full validation package, a automatic removal of reject cartons, a reject system and a shingling conveyor to maintain high throughput.

RF POUCH

The RF Pouch is the ideal solution for automatic feeding, printing and/or labelling or resealable pouches, asymmetric products and poly bags. Using vacuum technology, the RF Pouch can transport a wide range of pouches and other flexible packaging. The system is able to pick the product from a stack of multiple products and then place it onto the conveyor for printing or labelling before transferring the marked pack neatly onto another stack of completed products, ready for collection.

RF CASE FEEDER

The RF Case Feeder is the perfect solution for the automatic feeding of outer case packaging (boxes) in their flat form. The RF Case Feeder has been designed to handle a large variety of outer case secondary packaging. Its twin conveyor design allows for the easy separation of boxes onto the conveyor, this then allows them to be individually printed or labelled, ready for operator removal.

We can offer the complete Rotech Range of Machines for further information contact Total Food Machines