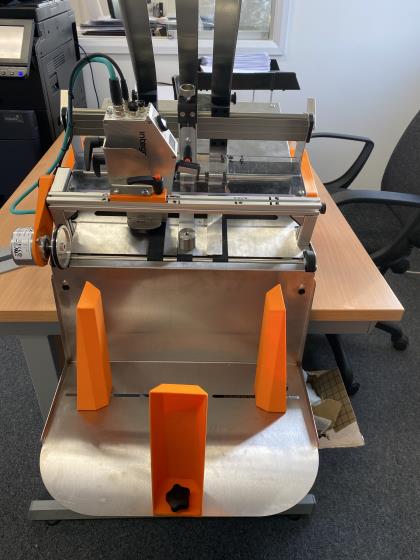

Hacona V-TYPE and VI-TYPE high performance industrial vacuum impulse sealers

The Hacona V-TYPE and VI-TYPE machines are using the MSB technology. Modular Sealing Bar is an innovation which enables the sealing bar width to be changed within few minutes. All temperature, time and closing pressure settings automatically adjust to compensate for the change in width! The maintenance of the used sealing bar can be carried out easily in parallel and the packaging process can go on.

The machines can be used to securely seal filled bags suitable for sealing PE, PP, PVC, aluminium or any other laminated film with sealable inside layer.

Impulse controlled sealing assures high working safety and the sealing wire gets hot ONLY when the sealing bars are closed and in sealing cycle. This provides a high level of safety at work and offers an environmentally friendly – energy saving impulse sealing - eco energy saving - solution. The machine connect to a 230 V (the USA versions to 110V) power supply.

This innovative system contains a single industrial sealing unit with seven interchangeable sealing bar widths - 420, 620, 820, 1020, 1320, 1520 and 2520 mm.

Impulse controlled sealing: the sealing wire gets hot ONLY when the sealing bars are closed and in sealing cycle

All machines from the V-TYPE high performance industrial vacuum impulse sealers family work with a 8 mm (app. 0,3 inch) wide impulse sealing wire. The sealing length depends always on the size of the sealing bar. All thermoplastic (heat sealable) films up to 1200 micron total material thickness can be sealed easily and air tight. The total surface of the sealing wire is PTFE tape coated. This avoids sticking of the bag material to the sealing wire.

The maximum sealing temperature is 230°C. (with Extra 1 program 260°C)

These sealers has a temperature sensor in the sealing bars. The set sealing and cooling temperature is constant. The machine can be validated.

Materials suitable for sealing:

• PE (LDPE, HDPE), PP, PA, PVC, BOPP and other thin laminated films

• ALU (aluminium with sealable layer inside)

ll the V-TYPE and VI-TYPE high performance industrial impulse vacuum sealers can be ordered with cutting wire. This will cut the top of the foil. The top of the foil must be removed after the sealing process easily but manually.

It can be used for PE foils. For all other type of foils sample is recommended. Aluminium foils can not be cut.

The sealing wire of the film sealing machine heats up only when the sealing bars are closed. The sealing is activated when the sealing bars are totally closed. The operator have to close the sealing bars with electrical foot pedal, with two hand start buttons or from LCD screen START button. The pneumatical cylinders starts to close the sealing bar with a small force till the safety sensor senses, then the sealing bar closes with a big force, and stays closed during the sealing and cooling cycles.

There sealing programs contains sealing - cooling times and temperatures, power settings which are all electrically controlled. There are 30 program that can be independently adjustable through the HMI - an 5.7” LCD Touch Display control unit

The sealing is started only when the sealing bars are totally closed and open when the sealing wire is cool down. NO risk of getting burn injuries. If the hand is between the sealing bars while closing the safety system opens the sealing bar again without closing with big force!

ACC - Active Cycle Control system

Any parameters of sealing (temperature, time, power) can be set and controlled by ACC independently of each other. Using the ACC System sealing will be validated (quali?ed). Due to the system, every sealing process can be realized and repeated in?nitely by the same parameters.

• No more overheating of sealing wires

• No readjustment of parameters at continues work is needed.

In standby mode the machine consumes only app. 30 W / hour (energy saving impulse sealing - eco energy saving) electrical power.

The machine is designed to seal filled bags.

The safety level function is very useful if you want to be sure, that only authorized personnel has access to the given safety levels and to make modifications in program, adjusting program values or choose programs. There are 4 levels available:

• 1st level: user can work with the chosen program

• 2th level: user can choose a premade program

• 3rd level: user can make new program

• 4th level: user can log in to service menu

Modified atmosphere is the practice of modifying the composition of the internal atmosphere of a package in order to improve the shelf life of the product. The need for this technology for food arises from the short shelf life of food products such as meat, fish, chicken, dairy, fresh fruits and vegetables in the presence of oxygen. From a microbiological aspect, oxygen encourages the growth of aerobic spoilage microorganisms. The reduction of oxygen and its replacement with other gases can reduce or delay oxidation reactions and microbiological spoilage and extend shelf lifetime.

The modification process generally lowers the amount of oxygen (O2) in the headspace of the package. Oxygen can be replaced with nitrogen (N2), a comparatively inert gas, or carbon dioxide (CO2).

V-TYPE: Orange painted for general industry

anodized aluminium - Stainless steel VI-TYPE: Stainless steel for food, pharmaceutical and chemical industry

Every machine has various options and build up solutions in different sizes. With our MSS (Modular Stand System - details here) solution we provide a flexible solution to optimize the machine for each production environment. From manual to semi-automatic process, from very small bag size to Big Bag product size.

For detailed information and technical sales support please contact our sales team.

Please email Total Food Machines@packs-it.com or call 02890 994 202