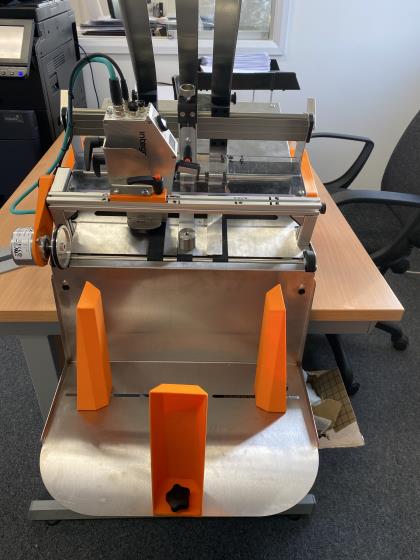

Jeros Untensil Washers

Jeros Utensil Washers are extensive offering so many applications please click the link at bottom of page to see which machine will suit your purpose.

Optimum handling

JEROS-Utensil Washers have a specially designed lid which opens fully to allow easy operation and loading without causing back strain to operators. The special JEROS features provide easy installation of the machines. Even in the smallest production areas. Further, the machine can be used as a sink when not in use as an automatic Utensil Washer.

The flush hose

The flush hose makes it possible to reuse the wash water e.g. for cleaning the floors. The flush hose can also be mounted on the mixer tap if required.

Mixer tap

Built-in mixer tap allows washer to be used as a sink with separate drainage.

Fulfils the highest hygiene standards

Even the most persistent dirt is removed! The fully automatic detergent dispenser ensures the optimum dosage of soap. The powerful pumps and rotating wash arms provide a brilliant wash result. The end rinse pump guarantees a constant temperature of 85°C during the entire rinse period and sanitisation of the utensils is achieved. An additional advantage of the high temperature rinse is the fast drying of utensils by evaporation, a rinse aid can be automatically added to assist with this process

The New Generation

The 9100 Series comprises a total of five new models: 9110 / 9115 with rotating wash systems and 9117 / 9120 / 9130 with wash frame system.

Inside, the machines have been thoroughly redesigned, focusing on hygiene and easy cleaning. The inside surfaces and rounded to ensure quick and automatic flow of water back to the filter and pumps.

Filters, wash arms and wash frames come in electropolished surface finishes leaving the stainless surface completely smooth to prevent dirt from sticking to surfaces of the machine. This makes it easier to clean and maintain the machine

Efficiency and optimum hygiene safety, including HACCP, form the base of the JEROS, set of values.

Energy saving up to 25 %

All the machines are now available with "i-version" as standard. This means that all machines have water saving rinse nozzles and that both the wash and rinse tanks are isolated, as also the lid is with double wall and isolated. The machines therefore require less operating power, resulting in energy and water savings of up 25 % for all the models.

It is also possible now to set the machines to "auto off", as required, so that they do not have to be left unnecessarily in standby mode if they are not used for prolonged periods of time, etc.

Eco wash

As standard all models includes an environmentally friendly "ECO wash" programme for less dirty objects. Pushing "ECO wash", the machines wash with a reduced wash temperature and use less soap. Still the rinse with 85° C hot water for guarantee of hygienic result

New double Micro-Filter:

Unique double filtration system, with a progressive micro-fine filter, provides an efficient filtration of the wash water - thus entails a perfect washing result with less soap consumption and minimal water consumption

Larger particles are collected in a coarse filter, were as smaller particles are captured in the self cleaning micro-fine filter. During the washing/rinse process, the collected particles are drain let out of the micro-fine filter from the bottom, just as well from the surface of water. this ensure a constant optimum wash water quality

file:///C:/Users/david/Downloads/_media_63682_9100serie_uk.pdf

For further information contact Total Food Machines on 02890 994 202 or email sales@totalfoodmachines.com